Innershield™ screens

Long Life in Severe Service

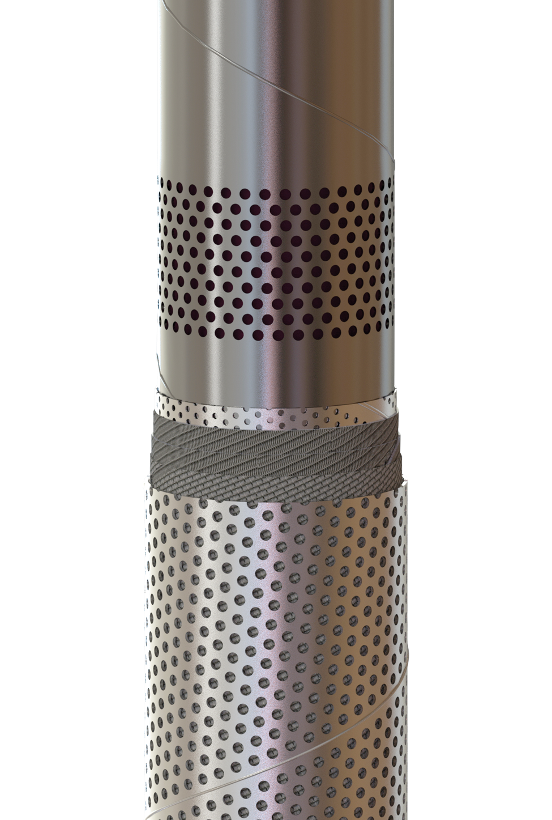

InnerShield™ sand-control screens provide long life and optimized production in wells with harsh downhole conditions. They resist erosion and abrasion with a patent-pending design that directs and disperses fluid flow to avoid localized hot spots and maintain the integrity of the filter media.

Designed for Durability

In sand screens, erosion occurs from the inside out and initiates at perforations. InnerShield™ screens are designed to neutralize these factors.

InnerShield™ screens are built using a patented process that combines base pipe, support core, filter media, and protective shrouds into a single, unitized joint with layers locked tightly in place.

The inner shroud is manufactured so its hole pattern is offset from the base pipe perforations, effectively diffusing the incoming fluid over the entire screen surface and preventing damaging localized erosive conditions. Furthermore, standoff is optimized to minimize pressure drop and maximize the effective filter area.

The result is a sand screen that lasts longer in the toughest downhole conditions.

Advantages

- Erosion and abrasion resistance

- Mechanical strength

- Reliable filtration

- Unitized cartridge design

- Simple, fast installation

- Compatible with sintered mesh construction

- Design and production flexibility

- Meets the toughest producer and service company testing requirements

Applications

Innershield™ screens perform reliably in your most challenging applications:

- Wells with severe downhole conditions

- Open-hole and cased-hole completions

- Stand-alone completions

- Gravel-pack and frac-pack completions

- Vertical, deviated and horizontal completions

- High flow-rate producers

- Long and extreme-reservoir-contact wells

- High GOR wells

Flow Distribution

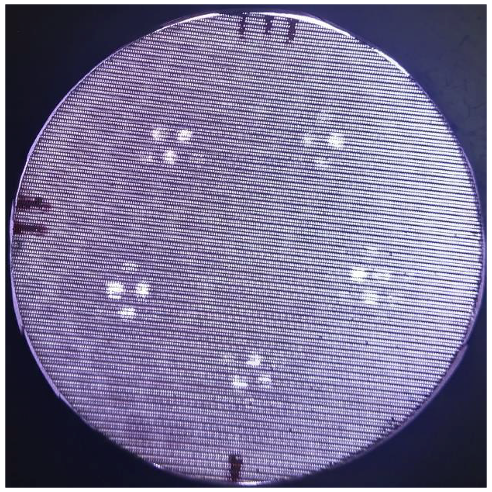

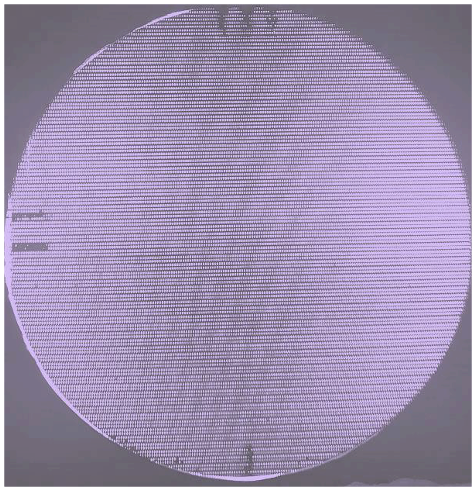

Testing confirms improved flow distribution through the screen by the addition of the inner shroud. The InnerShield® screen exhibits significantly reduced exit velocity of fluids underneath the screen compared to a conventional screen design, thereby protecting the screen against erosion (after SPE 208817).

T = 24 Hours

T = 96 Hours

Erosion damage on a conventional screen vs the InnerShield Screen (test performed at 72 gpm through a 4in screen disk with 4g/L 360mesh SiC Grit – after SPE 208817).

Dimensional Data

Downloadable Resources

Proven Worldwide

UniScreen™ technology is protected under the following patents:

U.S. Issued Patent No. 10,981,090 and 10,895,134

U.S. Patent Pending No. 17/472,306, 18/101,508 and 63/438,746

EU Patent Pending No. EP22161156

Saudi Arabia Patent Pending No. 122431294

UAE Patent Pending No. P6001431/2022

Kuwait Patent No. 931367

Brazil Patent Pending No. BR1020210223987